Process Flow

Process Flow of Precision Cold Rolled Stainless Steel Strip and Sheet

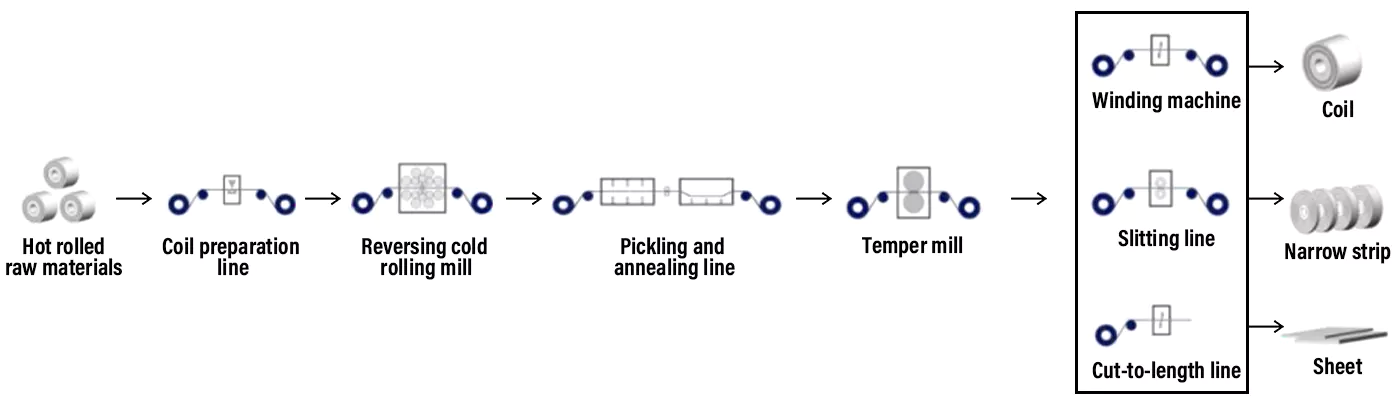

Process Flow of Pickling Annealing Cold Rolled Stainless Steel Strip and Sheet

The process involves multi-pass rolling of hot-rolled stainless steel raw materials through a cold rolling mill to achieve the target thickness. Following rolling, pickling and annealing are applied to attain the required mechanical properties and surface finish. Finally, a temper rolling process optimizes the surface quality of the strips. Strips produced by this process feature a 2B surface finish and belong to the soft temper cold-rolled stainless steel category in terms of mechanical properties.